Client: Surrey Heath Borough Council

Role: Principal Contractor

Scope

- Replacement Leadwork

Liquid Applied Waterproofing

Anti-Slip Walkway

Details

-

- Occupied theatre roofs

Replacement leadwork due to theft or deterioration

>630m2 rewaterproofed using Sikalastic 618 waterproofing system

Fully integrated anti-slip walkway for the fire escape - Detailing to complex geometries across the roofs

- Phased around scheduled performances to minimise disruption

- Occupied theatre roofs

Camberley Theatre is a much loved community venue, hosting local pantomimes, touring productions, rehearsals and events year round. Built in 1966, the building has long been a cultural focal point but time had taken its toll on the roof coverings with the existing felt system showing varying levels of deterioration to the three roof areas.

Replacing the stolen and deterioration lead flashings demanded a high level of precision and care at every stage of the process. The existing leadwork had not only been compromised by theft but was also showing signs of age-related fatigue and failure, which increased the risk of water ingress into the structure below, putting the theatre’s operations at risk. All the remaining fragments were thoroughly traced, loosened and carefully removed to avoid disturbing adjacent masonry and roofing materials. Particular attention was given to preserving the integrity of the substrate and preventing further damage during the removal phase.

Once the area was fully prepared, new chases were accurately set out and formed to the correct depth and alignment, ensuring they would adequately accommodate the replacement lead. The surfaces were thoroughly cleaned and dressed to provide a secure and stable fixing point. New lead flashings were then expertly installed, allowing for appropriate expansion and contraction. Each section was neatly wedged, pointed and sealed to create a robust, continuous waterproofing termination that integrated seamlessly with the existing roof structure.

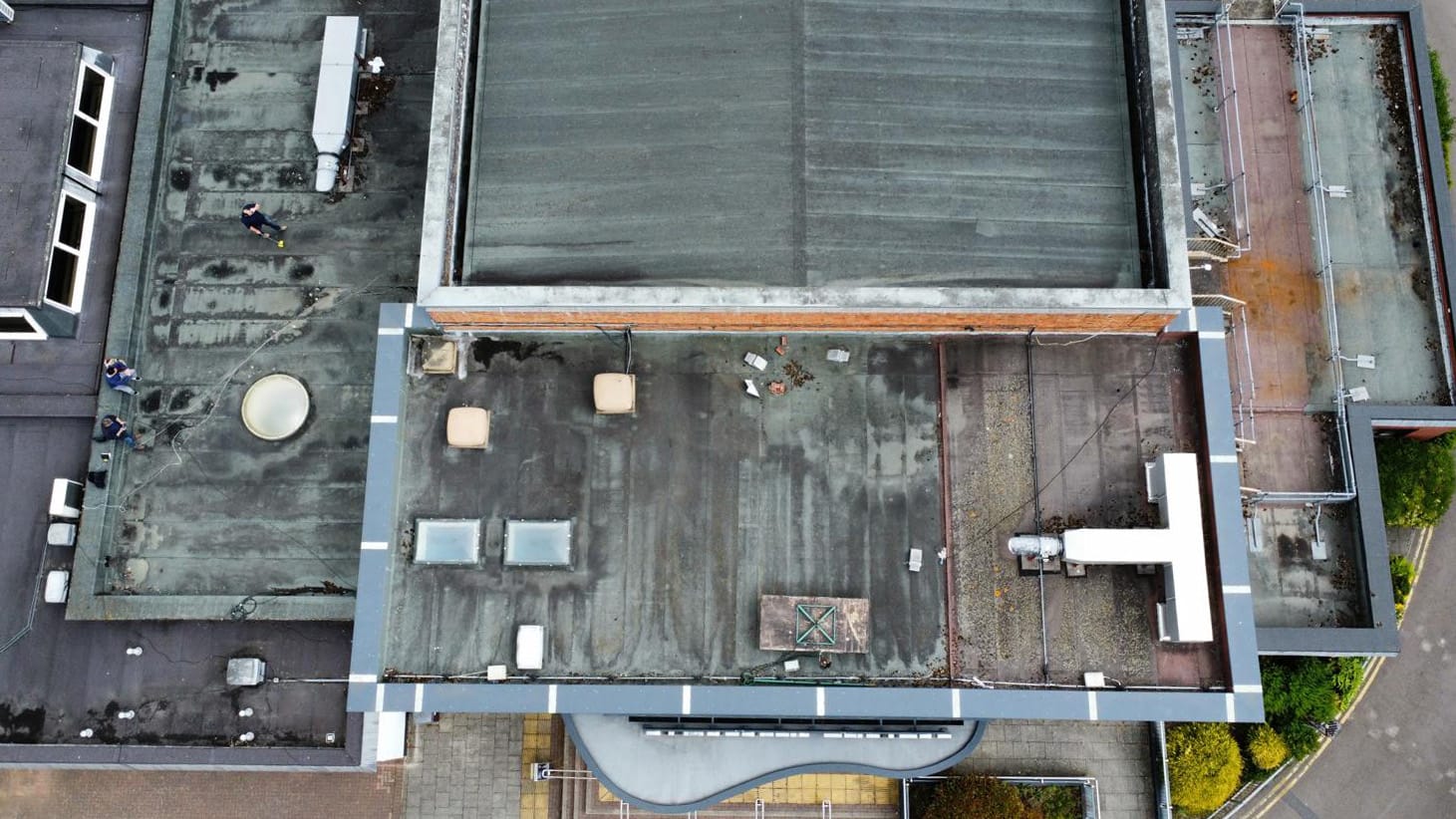

Thorough jet washing and surface preparation was completed across the various roofs, ensuring that the new waterproofing system would perform reliably while respecting the existing structure. The 634m2 of flat roofs were overlaid with Sika’s Sikalastic 618 liquid waterproofing system, providing a seamless and fully bonded protective layer. This phase necessitated a high degree of technical accuracy, particularly around the theatre’s numerous bay windows, window cills, upstands and the complex roof geometries across the North-West and South-West elevations.

These intricate junctions and transitions required careful preparation and application to ensure complete encapsulation and long-term durability. Each detail was meticulously executed to maintain watertight integrity while achieving a clean, consistent and uniform finish across the entire roof area.

A key feature of the refurbishment was the South-East roof, which forms part of the theatre’s emergency fire escape system. In addition to re-waterproofing, this area required the installation of a highly visible red anti-slip walkway, fully integrated into the waterproofing system. The result provided a safe, clearly defined access route while delivering a bold visual contrast against the slate grey roof finish.

Maintaining a fully operational fire escape throughout the refurbishment presented a significant challenge. Temporary controlled passageways were introduced and the works were broken down into tightly managed micro-phases. Temporary coverings ensured continuous safe passage, allowing the theatre to meet safety requirements without interruption.

As a fully occupied venue with limited back-of-house access and only a small rear loading area, the project demanded careful planning. A self-contained site compound was established to avoid disruption to the theatre’s operations, while scaffolding was designed to keep public routes, including the main entrance, clear at all times. With scaffolding restricted to the rear elevation only, material deliveries, waste removal and on-site movements were coordinated and often scheduled during short off-peak windows.

Throughout the programme, the theatre remained open, hosting daily rehearsals, community activities and a full performance schedule. Close daily coordination with theatre management ensured that noisy or intrusive works were planned outside performance times, preserving the visitor experience and minimising disruption.

Despite a challenging 8 week programme and the complexities of working on an occupied, operational building, the works were completed 2 weeks ahead of schedule. This early completion protected the theatre’s peak season and demonstrated efficiency, adaptability and commitment to delivering under pressure.