Corrosion Management

Corrosion of reinforcing steel within concrete is a complex issue that requires more than just conventional patch repairs. Addressing only visible defects often leads to the ‘incipient anode’ effect, where a newly repaired, alkaline area is placed next to an unrepaired section with lower alkalinity. This disparity can create new corrosion sites around the repaired area, undermining the effectiveness of the repair.

Although building facades differ from car parks and typically encounter fewer chloride-related issues, they may still require corrosion management. Factors such as the nature of identified defects, the type of reinforced concrete used (pre-cast vs in-situ) and the buildings proximity to marine environments all play a role in determining the need for corrosion control.

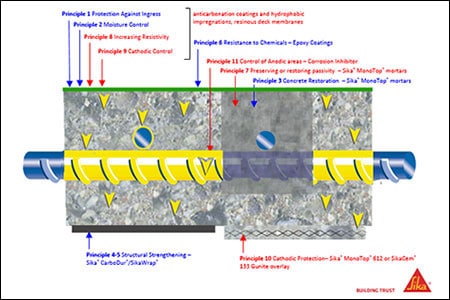

Concrete repairs usually involves replacing only a small portion of the damaged area, leaving much of the structure exposed to ongoing corrosion risks. To mitigate these risks, it is essential to implement a robust Corrosion Management strategy.

Corrosion management is a crucial element of successful structure refurbishment, with approaches tailored to the client’s specific needs and budget. Some clients may seek a short-term, cost-effective repair solution, while others prioritise a long-term strategy to ensure durability and structural integrity.

Understanding the root causes of corrosion – such as the effects of de-icing salts and carbonation – is vital when planning a repair and protection strategy. Corrosion is driven by multiple factors, including water, oxygen and salt chlorides, all of which contribute tp the deterioration process.

We use a range of advanced techniques to effectively manage corrosion in reinforced concrete structures, including:

- Multi-functional Corrosion Inhibitors (MCI’S)

Vapour-phase Corrosion Inhibitor (VCI’s)

Sacrificial Galvanic Anodes (Embedded)

Impressed Current Cathodic Protection (ICPP)

These techniques are designed to preserve the structural integrity of your concrete assets, ensuring long-term durability and protection. By addressing corrosion at its source, we deliver bespoke solutions that meet the unique needs of each project, whether it’s a car park refurbishment or the protection of building facades.